The SMDP Optimum is a version of the system designed to work within one company. It was created for the needs of customers looking for a compromise between the functionality of the Professional version and the price of the Standard version. KDP100 OPTIMUM dispenser controllers exchange information and require a permanent connection with the PC application ARCCAN SMDP OPTIMUM. A maximum of 5 dispenser controllers can be defined in the program. All vehicles and recipients are entitled to use all distribution points defined within the company.

The DEMO SMDP OPTIMUM version is available at: https://demooptimum.smdp.online

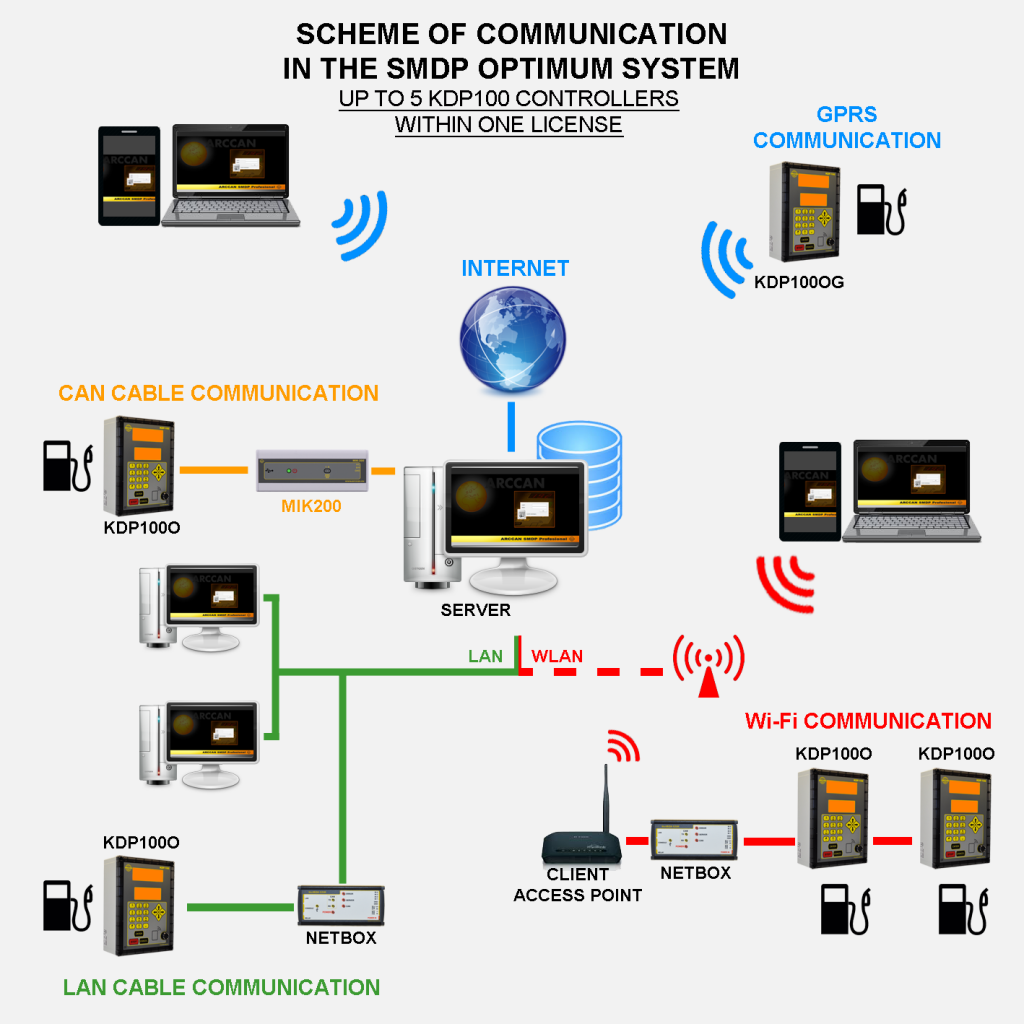

The whole process of configuring KDP100 dispenser controllers is extremely easy and is carried out from the ARCCAN SMDP OPTIMUM PC software. Two-way communication between the program and controllers can be executed:

- by CAN cable – using the MIK200 communication module connected via USB to any computer in the network,

- by LAN cable – using the NETBOX communication module connected to the LAN socket,

- by Wi-Fi – using the NETBOX communication module and Access Point connected to the company’s Wi-Fi network,

- by wireless GPRS – internet communication using the GSM cellular network.

SMDP OPTIMUM system functions:

- authorization in the system before refueling (selected generally for the whole company):

- double – for refueling, the vehicle AND the recipient must be logged in,

- single – refueling requires a vehicle OR recipient login,

- single + name – for refueling, it is required to log in the vehicle or the recipient, the second data must be entered on the keyboard of the dispenser controller,

- methods for identifying vehicles, recipients, operators in the system (a method chosen individually for each group):

- electronic identifier (chip – COD110 or contactless card – COD100),

- PIN code,

- by electronic identifier with additional confirmation by a PIN code,

- unlimited number of vehicles and recipients,

- possibility of supporting in one program up to 5 KDP100 OPTIMUM dispenser controllers, assigned to the same or different tanks,

- possibility of requiring to enter the mileage during authorization (in kilometres or hours, depending on the vehicle),

- possibility of choosing recipients or vehicles who will not see the amount of liquid dispensed during refueling,

- possibility of setting important refueling times (time from authorization to lifting the nozzle, waiting time for 0.5 l of liquid, time between successive PULSER pulses),

- when adding operators, predefined or individual rights are assigned (selection of system functions in which the operator can make changes or have only the view access),

- calculating the level of liquid in the tank, the function of warning about reaching the alarm level, and the level of pump blockage,

- a module for creating reports according to own needs by each operator individually,

- analytical and graphical module for creating reports extended by calculating the distance and average liquid consumption per 100 km or 1 h,

- extensive data filtering options when creating reports,

- calculating the average liquid consumption per 100 km or 1 h by vehicles with signaling of exceeding norms,

- parameterization of selected “Full” refueling for consumption analysis + module for automatic detection of additional refueling,

- possibility to export data to a spreadsheet or a PDF,

- possibility of adding external refueling to the system,

- possibility of assigning liquid collection limits to selected recipients and vehicles (multiple simultaneous limits for different liquids to choose from: one-time, daily, weekly, monthly or yearly),

- data exchange between KDP100 OPTIMUM controllers about the use of limits by recipients and vehicles,

- option of grouping vehicles and recipients in the program (groups can be freely defined by the operator),

- e-mail notification module (reporting: each refueling, reaching the alarm and critical level of the tank, calibration initiated or performed, significant loss of liquid in the tank, tank loadings, tank leak, zero refueling, SKP failure),

- option to enable preselection of the amount of liquid to be dispensed before refueling for whole company,

- calibration by measurement or change of a factor,

- possibility to correct the calibration factor using a computer,

- presentation of tanks on a map,

- emergency refueling function (implemented with one-time codes),

- manual refueling function (implemented with one-time codes),

- possibility of cooperation with the system for measuring the actual amount of liquid in the tank and detection of inter-shell space – SKP,

- possibility of temperature compensation of the Diesel fuel dispensed up to 15°C,

- possibility of remote update of KDP100 OPTIMUM,

- possibility of migration of dispenser controllers and software to higher versions (Professional, Enterprise),

- operation in different languages (Polish, English, German, Russian, Lithuanian, Czech).